Blog

Navigating New Product Development: Critical Steps for Successful Planning

In the ever-evolving landscape of industries and markets, new product development (NPD) has become a cornerstone of innovation and growth. Companies are constantly striving to bring fresh and innovative products to market to meet the changing demands of consumers. However, developing and launching a new product is a complex journey that requires meticulous planning and execution.

For a more in-depth visual explanation, check out our accompanying YouTube video.

Introduction

New Product Development (NPD) is the process of bringing innovative products from concept to market. Effective NPD planning is crucial in the industrial sector, where technological advancements and consumer preferences change rapidly. This article will explore the NPD project planning process, emphasizing its significance in the industrial and manufacturing sectors.

Understanding New Product Development (NPD)

Defining NPD

New Product Development (NPD) is a comprehensive process that encapsulates the entire journey of transforming an initial idea or concept into a tangible and market-ready product that effectively addresses the needs and preferences of customers.

This multifaceted process comprises several stages, starting from the inception of creative ideas and progressing through the intricate steps of development, testing, and ultimately culminating in a successful market launch. Each stage is integral to shaping the product’s overall success and impact.

Importance of NPD in the Industrial Sector

The significance of NPD is particularly pronounced in the dynamic and competitive landscape of the industrial sector. To remain competitive and relevant, companies within this sector must continually adapt to evolving market demands and technological advancements. Effective new product development (NPD) is essential to succeed in this environment. It allows manufacturers to stay ahead of the competition by introducing new and innovative solutions that meet current market demands and anticipate future trends.

By embracing a robust NPD strategy, industrial companies can position themselves as pioneers in their respective markets. This strategic approach enables them to identify and seize opportunities for growth, differentiation, and competitive advantage. Through systematic NPD practices, manufacturers can harness the power of innovation to create products that satisfy customers’ needs and resonate with their preferences and expectations.

The NPD Project Planning Process

Idea Generation and Conceptualization

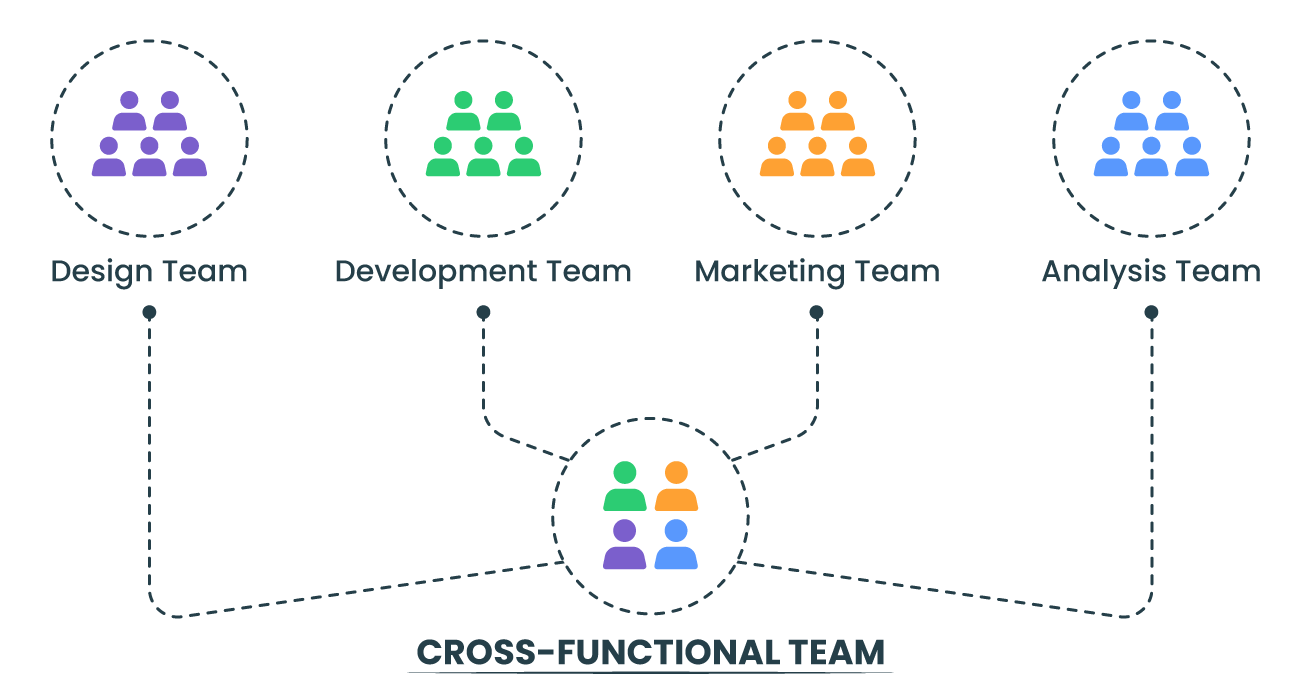

The journey begins with generating creative ideas and refining them into viable concepts. Cross-functional teams collaborate to brainstorm and identify potential product concepts that align with market trends.

Market Research and Analysis

Thorough market research is essential to understand customer preferences, competitors, and potential gaps in the market. This data guides the development of a product that addresses specific needs.

Feasibility Assessment

The feasibility of turning a concept into a reality is evaluated during this phase. Factors such as technical feasibility, resource availability, and financial viability are analyzed.

Design and Development

The product’s design and development phase involves creating detailed specifications, prototypes, and functional models. Iterative testing and refinement ensure the product meets quality standards.

Prototype Testing and Validation

Prototypes undergo rigorous testing to validate their performance, functionality, and user experience. Feedback from testing informs necessary adjustments.

Manufacturing Planning and Capacity Assessment

Manufacturing planning involves determining production processes, sourcing materials, and assessing production capacity. Capacity planning ensures efficient production without compromising quality.

Marketing and Launch Strategy

Developing a comprehensive marketing and launch strategy is crucial for creating awareness and generating anticipation among potential customers.

Commercialization and Distribution

The product is officially launched and made available to customers through distribution channels. Monitoring initial market response helps refine the product’s positioning.

Stage-Gate Methodology’s Role in NPD

What is the Stage-Gate Process?

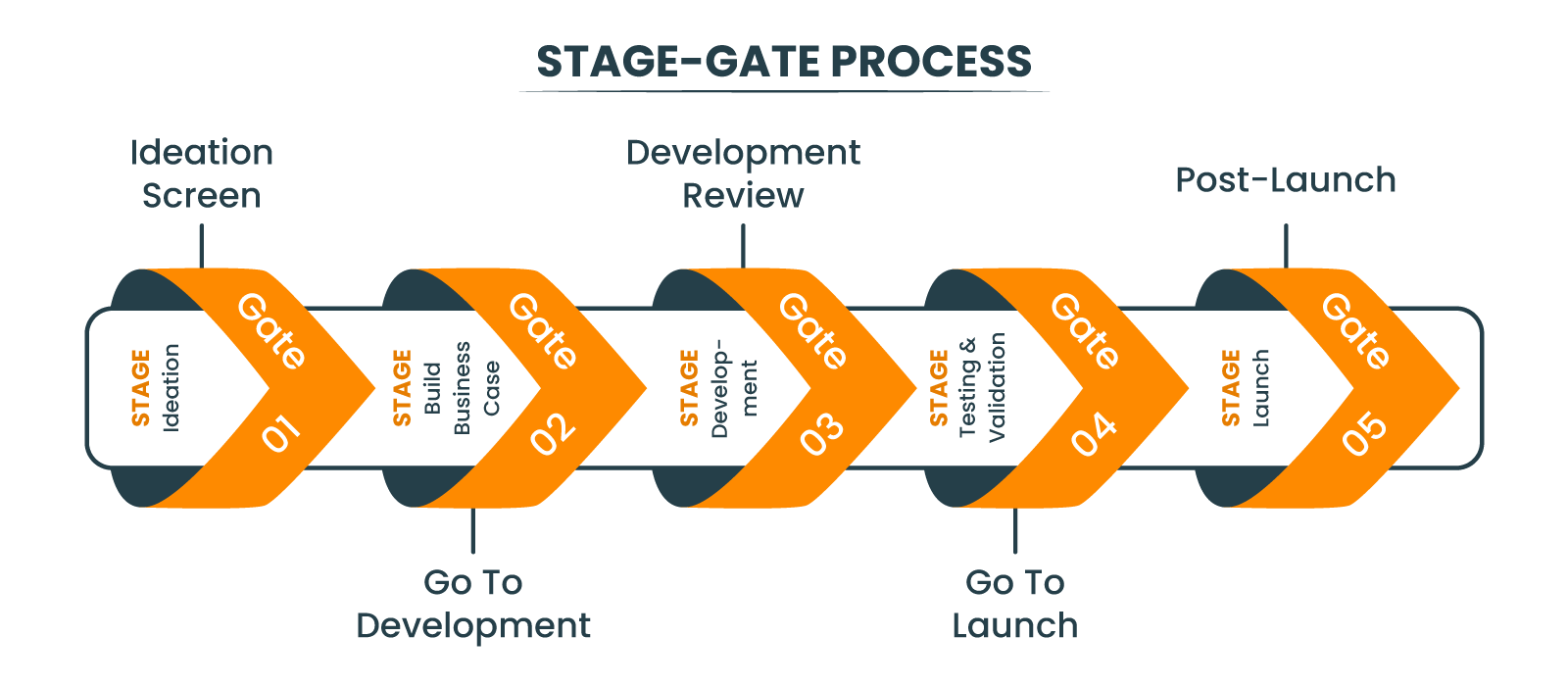

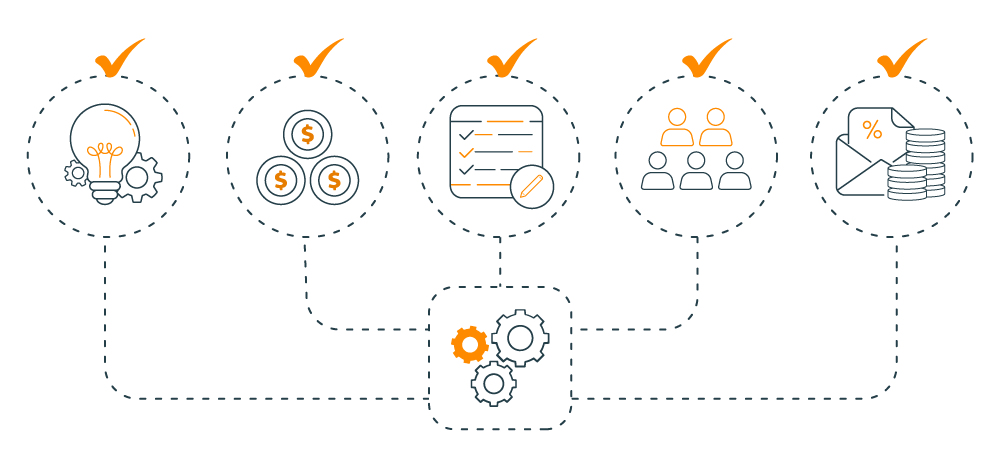

The Stage-Gate process is a well-defined and structured approach utilized in New Product Development (NPD). It organizes the NPD journey into a series of stages or gates, each representing a crucial development phase. At each gate, cross-functional teams assess the project’s progress, make informed evaluations, and collectively decide whether to proceed to the next stage. This approach ensures the project aligns with strategic goals, customer expectations, and market demands.

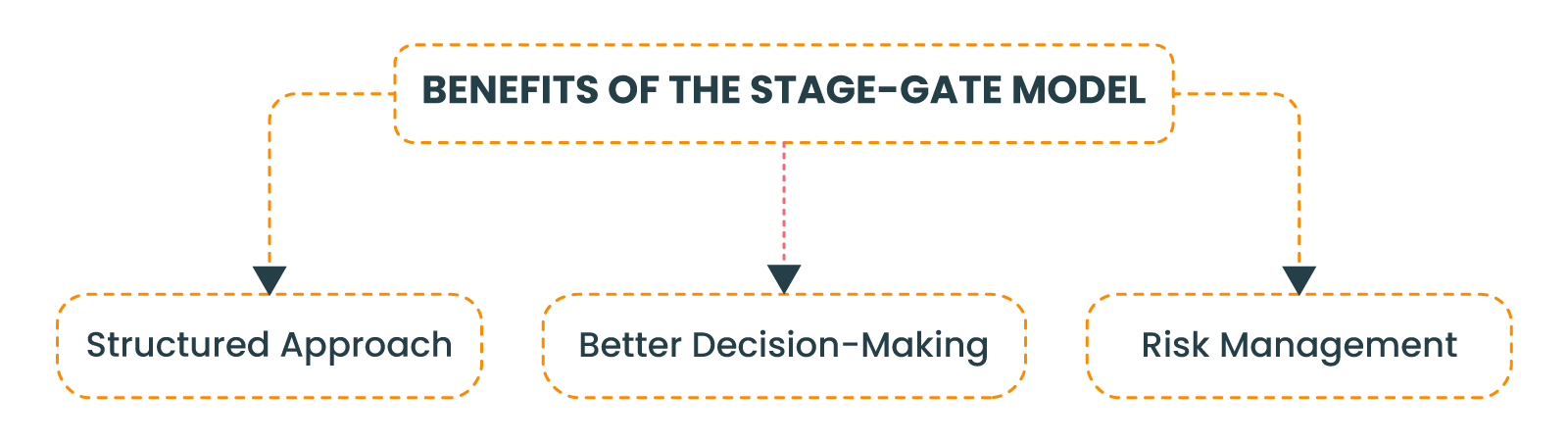

Benefits of the Stage-Gate Model

The Stage-Gate model plays a pivotal role in the success of NPD initiatives. It offers a structured framework that enhances accountability by clearly assigning responsibilities for each stage to relevant teams or individuals.

Moreover, it facilitates effective risk management by providing opportunities to identify and mitigate potential risks at various checkpoints. The model also optimizes resource allocation by allowing companies to allocate resources based on the project’s progress and potential.

It safeguards against costly errors by ensuring each stage is completed successfully before advancing, minimizing the risk of proceeding with flawed concepts. The Stage-Gate model is a proven methodology that empowers companies to navigate NPD with structure, efficiency, and strategic precision.

Best Practices for Speeding Time to Market

Leveraging best practices can significantly expedite the process, ensuring companies stay ahead of the curve.

Cross-Functional Collaboration

One of the cornerstones of efficient NPD is cross-functional collaboration. Breaking down silos between departments fosters open communication and facilitates the exchange of ideas, knowledge, and expertise. When teams collaborate seamlessly, decision-making becomes streamlined. This collaboration accelerates the overall NPD timeline, as there is reduced time spent on conflicting opinions and miscommunication. By harnessing the collective intelligence of various teams, companies can swiftly navigate through each stage of the NPD process.

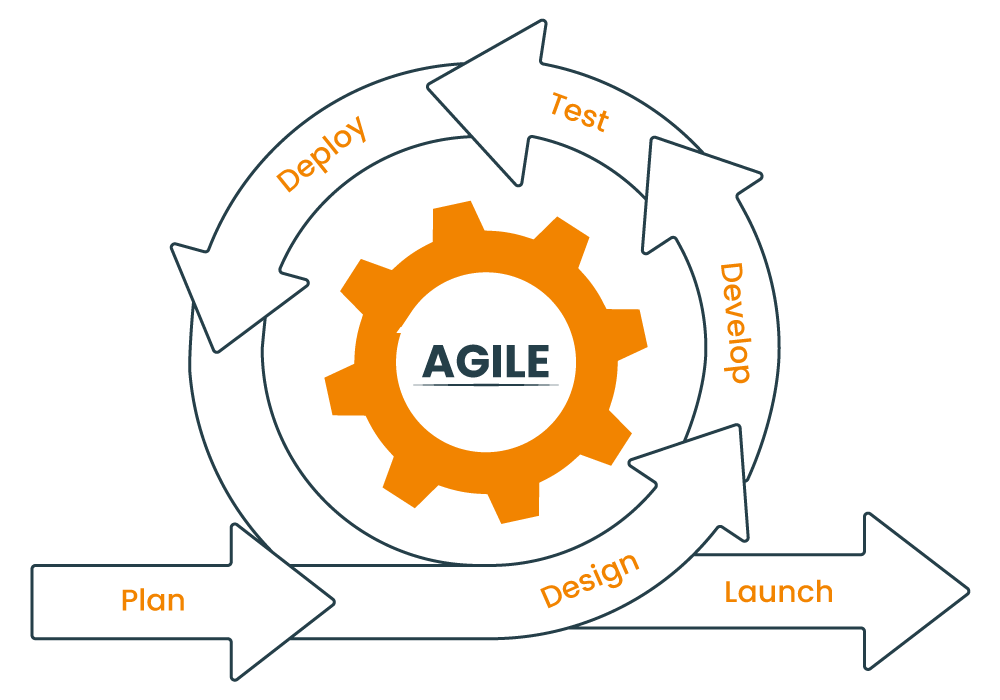

Agile and Iterative Approach

Adopting an agile and iterative approach is paramount for expediting NPD. An agile methodology enables teams to remain flexible and adaptive to changes, feedback, and evolving market conditions. The iterative process involves creating and refining prototypes in cycles, allowing for incremental improvements. This approach ensures potential issues are identified and addressed early in the development cycle, reducing delays and rework. By continuously refining the product based on feedback, the outcome aligns more closely with customer expectations, accelerating time to market.

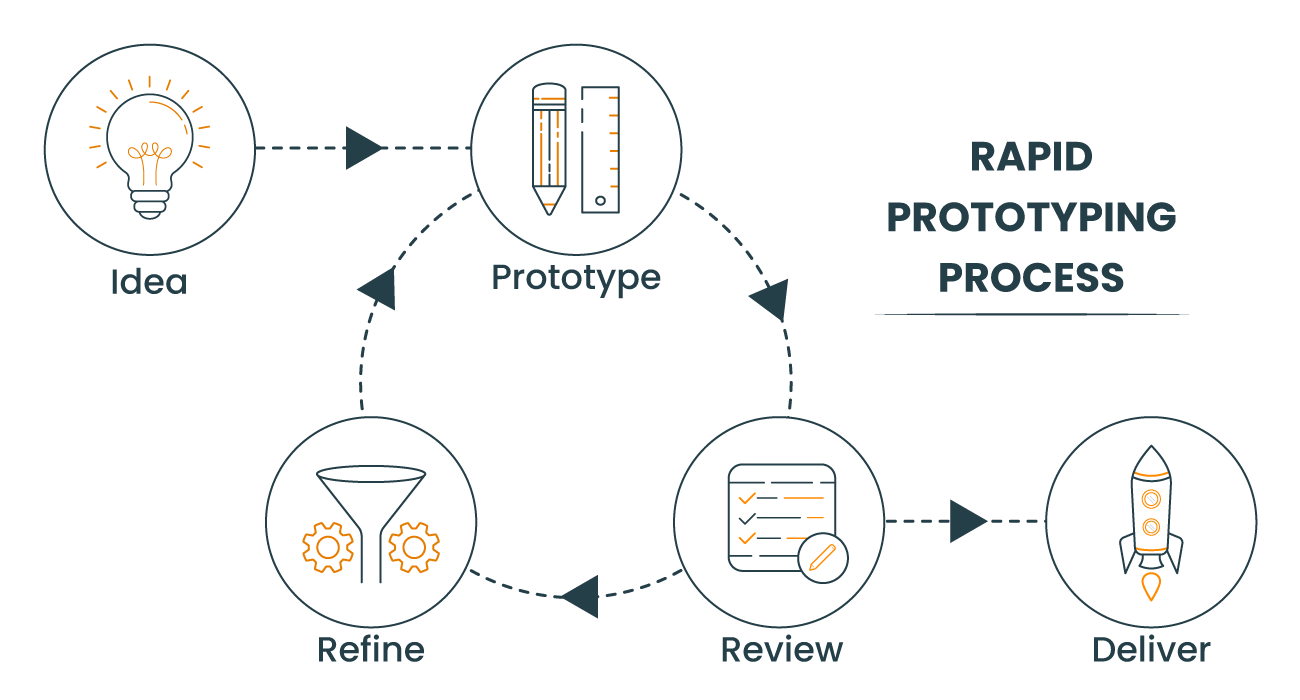

Rapid Prototyping

The significance of rapid prototyping cannot be overstated in accelerating NPD. Creating quick prototypes offers a tangible representation of the product, aiding in visualizing its features and functionalities. This early visualization facilitates better communication among teams, stakeholders, and customers. Rapid prototyping lets companies identify potential challenges or improvements early, enabling faster iterations and adjustments. This iterative process mitigates the risk of last-minute changes, ultimately contributing to a quicker and smoother journey to market.

Efficient Resource Allocation

Streamlining resource allocation is another practice that expedites NPD. By allocating resources strategically and in alignment with project requirements, companies can optimize the utilization of manpower, technology, and infrastructure. This prevents resource bottlenecks and ensures that the NPD process progresses seamlessly.

Capacity Planning

Capacity planning ensures that a company’s resources, including personnel, machinery, and facilities, align with the demands of new product development. Efficient capacity planning prevents bottlenecks and delays, enabling a smoother NPD process. It considers peak demand periods and allocates resources accordingly.

Data-Driven Decision Making

Leveraging data-driven insights is pivotal for informed decision-making. Analyzing market trends, customer preferences, and performance metrics provides a solid foundation for NPD strategies. Data-driven decision-making minimizes the likelihood of costly mistakes and misguided efforts, ultimately accelerating the development cycle.

Managing Risks and Uncertainties

Uncertainties are common in the dynamic landscape of New Product Development (NPD). Recognizing potential risks and implementing mitigation strategies can minimize disruptions, ensuring a smoother NPD journey.

Conclusion

Navigating the intricate journey of new product development in the industrial sector requires careful planning and execution. By adhering to the stages of NPD, incorporating capacity planning, and following best practices, companies can effectively bring innovative products to market. Embracing the challenges of NPD as opportunities for growth and improvement ensures long-term success in a competitive landscape.

* Stage-Gate® is a registered trademark of Robert G. Cooper. Used for descriptive purposes.

Task Management

Task Management

Customization

Customization