Blog

The Ultimate Guide to Manufacturing Project Management Software

Introduction: The Need for Smarter Manufacturing Project Management

Managing projects in manufacturing is no easy task. From coordinating production schedules and supply chains to ensuring quality control and resource allocation, every step must run seamlessly to avoid costly delays and inefficiencies. Yet, many teams still rely on generic project management tools that don’t fully address manufacturing’s unique complexities.

This is where manufacturing project management software makes a difference. With features like real-time scheduling, resource tracking, and manufacturing Gantt charts, the right solution helps streamline operations, improve visibility, and keep projects on track.

In this guide, we’ll explore why traditional project management methods fall short in manufacturing, the key challenges teams face, and how industry-specific software can drive efficiency and success.

Unique Project Management Challenges in Manufacturing

Project management in manufacturing is far more complex than in many other industries. Unlike standard business projects, where tasks are often linear, manufacturing projects involve overlapping processes, strict dependencies, and real-world constraints like material availability, machine capacity, and supply chain disruptions. Without the right tools and strategies, teams face inefficiencies that can lead to production delays, cost overruns, and missed deadlines.

- Complex Workflows & Dependencies

Manufacturing projects involve multiple phases—from design and prototyping to procurement, assembly, and distribution. Each phase depends on the previous one, making delays in one area ripple across the entire production cycle. Managing these interdependencies manually or with disconnected tools often results in bottlenecks and inefficiencies.

- Strict Deadlines & Production Schedules

Unlike office-based projects that allow flexibility, manufacturing operates on tight schedules. Production lines, supplier deliveries, and customer orders are all time-sensitive. A missed deadline in one phase can lead to backlogs, contract penalties, and lost revenue, making accurate scheduling and forecasting essential.

- Resource & Capacity Planning

Manufacturing requires efficient use of labor, machinery, and materials. Poor resource planning can lead to underutilized machines, workforce inefficiencies, or material shortages that disrupt production. A lack of real-time visibility into resource availability often results in last-minute adjustments that increase costs.

- Supply Chain Coordination

Manufacturers rely on a network of suppliers, vendors, and logistics providers to keep operations running. Disruptions in material procurement or delays in shipping can have cascading effects on production. Without proper project tracking, teams struggle to adjust schedules proactively, leading to downtime or unfulfilled orders.

- Compliance & Quality Control

Industries like automotive, aerospace, and pharmaceuticals have strict regulatory and quality standards. Managing compliance across different phases—design, production, testing, and distribution—requires a structured approach. Tracking certifications, audits, and quality checks manually can lead to errors, non-compliance risks, and costly recalls.

Why Standard Project Management Tools Fall Short

Many manufacturers attempt to manage projects with general-purpose project management software, spreadsheets, or manual processes. While these may work for simple projects, they fail to provide real-time visibility, automation, and industry-specific features required in manufacturing.

This is where manufacturing project management software steps in. The next section will explore the key features a manufacturing project management system must have to address these challenges effectively.

Key Features of Manufacturing Project Management Software

Manufacturing project management requires more than just task tracking—it demands precision, real-time coordination, and advanced scheduling tools. A dedicated manufacturing project management software provides industry-specific features that help teams streamline operations, reduce bottlenecks, and improve efficiency.

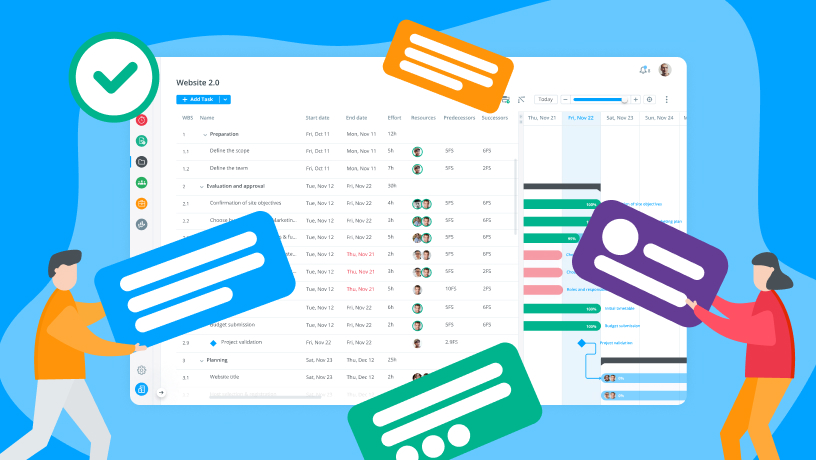

- Manufacturing Gantt Charts for Planning & Scheduling

A manufacturing Gantt chart is an essential tool for visualizing production schedules, task dependencies, and critical deadlines. Unlike generic Gantt charts, manufacturing-specific versions account for:

- Production phases – From design to final assembly.

- Machine utilization – Ensuring equipment is scheduled efficiently.

- Resource allocation – Managing materials, workforce, and supply chain inputs.

- Task dependencies – Adjusting schedules dynamically to avoid bottlenecks.

- Stage-Gate Process

Manufacturing projects, especially those involving product development, benefit from a Stage-Gate process to manage progress efficiently. This structured methodology helps teams:

- Break down projects into clear phases with well-defined deliverables.

- Implement go/no-go decision points to ensure quality and feasibility.

- Reduce risks by identifying potential issues early in the process.

- Improve collaboration between engineering, production, and management teams.

- Real-Time Resource & Workforce Management

Effective manufacturing relies on the seamless coordination of machines, materials, and labor. Project management software for manufacturing helps teams:

- Monitor resource availability in real time.

- Assign skilled labor efficiently based on production demands.

- Balance workloads across multiple projects and shifts.

- Prevent overuse or underutilization of critical equipment.

![]()

- Production Timeline Tracking & Milestone Alerts

Manufacturing operates on tight schedules where any delay can cause ripple effects throughout the supply chain. Advanced project management tools offer:

- Automated milestone tracking – Ensuring every phase progresses on time.

- Alerts for delays or conflicts – Allowing teams to act before minor issues escalate.

- Customizable dashboards – Providing a real-time view of project progress.

![]()

- Risk Management & Compliance Tracking

Quality control and compliance are critical in manufacturing. Project management software enables:

- Tracking of safety & regulatory requirements across different stages.

- Automated audits & certification monitoring for industry compliance.

- Incident tracking & issue resolution logs to improve safety and efficiency.

- Seamless Integration with ERP & Supply Chain Tools

A manufacturing project doesn’t operate in isolation—it connects with supply chain management, inventory tracking, and financial systems. The best project management software integrates with:

- ERP (Enterprise Resource Planning) Systems – Ensuring real-time access to production data.

- MES (Manufacturing Execution Systems) – Linking project tasks with shop floor execution.

- Procurement & Inventory Management – Preventing supply shortages or overstocking.

- Accounting & Financial Systems – Aligning project costs with budgets.

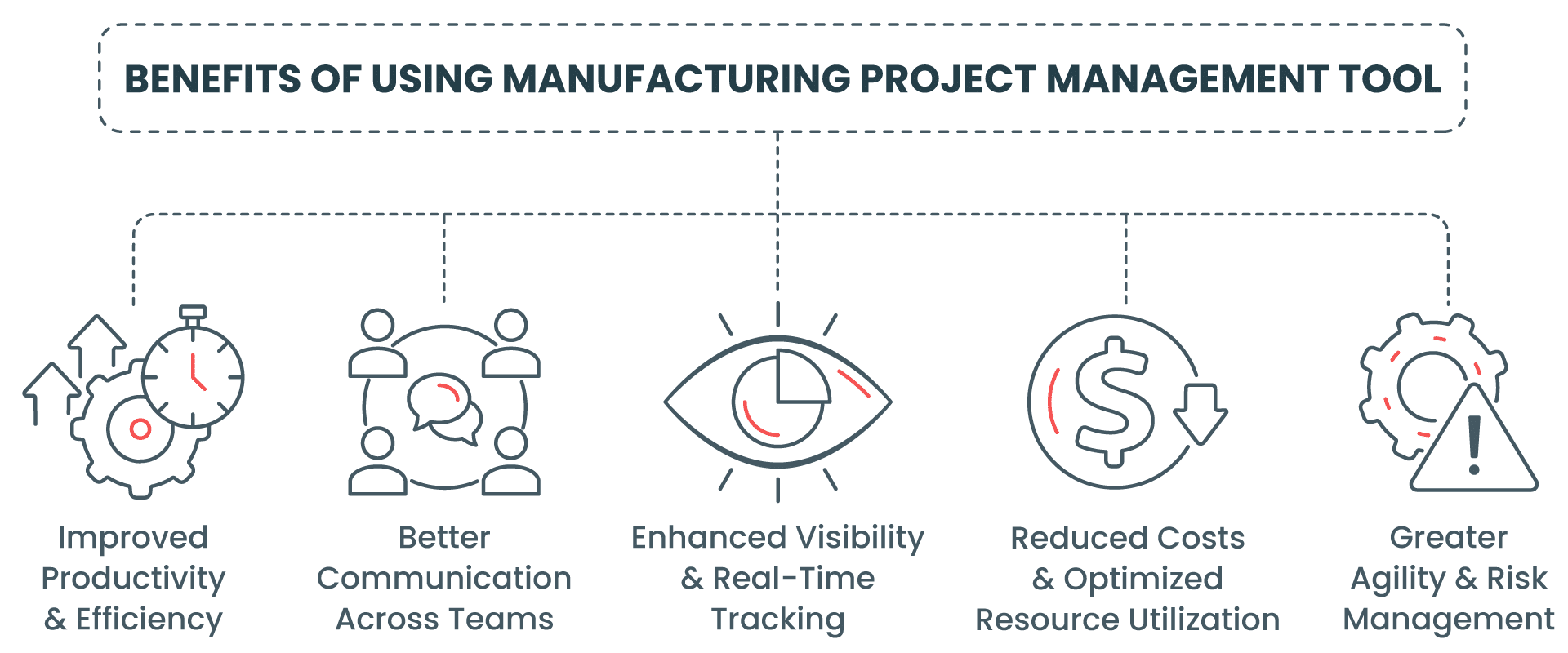

The Benefits of Using a Manufacturing Project Management Tool

Investing in manufacturing project management software is more than just an operational upgrade—it’s a strategic decision that directly impacts efficiency, cost control, and overall business performance. By centralizing project planning, automating workflows, and improving visibility, manufacturers can reduce errors, prevent delays, and optimize resources.

Improved Productivity & Efficiency

-

- Eliminates manual tracking by reducing reliance on spreadsheets.

- Automates scheduling & workflows for smoother production transitions.

- Optimizes resource allocation to prevent overloading machines or underutilizing staff.

Better Communication Across Teams

-

- Project updates are shared in real-time, keeping all teams aligned.

- Role-based access ensures the right people have the right information.

- Collaboration tools improve coordination between departments.

Enhanced Visibility & Real-Time Tracking

-

- Real-time dashboards provide a clear view of ongoing projects.

- Automated alerts highlight bottlenecks or risks before disruptions occur.

- Customizable reporting helps track costs, resources, and performance.

Reduced Costs & Optimized Resource Utilization

-

- Prevents overproduction by aligning production with demand.

- Reduces downtime with proactive maintenance scheduling.

- Tracks budgets in real-time to avoid overspending.

- Minimizes waste by optimizing material usage.

Greater Agility & Risk Management

-

- Built-in risk management tools identify and mitigate potential issues.

- Scenario planning tools adjust schedules and resources dynamically.

- Compliance tracking ensures regulatory requirements are met.

Best Practices for Implementing Project Management for Manufacturing

Successfully implementing project management software in manufacturing requires careful planning and execution. To ensure a smooth transition and maximize the benefits, consider the following best practices:

- Align Software with Business Goals – Choose a tool that adapts to your company’s specific needs and integrates seamlessly with existing systems.

- Train Your Team for Adoption – Provide comprehensive training to ensure all team members understand how to use the software effectively.

- Leverage Manufacturing Gantt Charts – Use visual scheduling tools to track production timelines, identify bottlenecks, and improve workflow efficiency.

- Monitor & Optimize Performance – Regularly review key performance indicators (KPIs) and adjust workflows to improve overall project outcomes.

- Align Software with Business Goals – Choose a tool that adapts to your company’s specific needs.

- Train Your Team for Adoption – Ensuring successful rollout and implementation.

- Leverage Manufacturing Gantt Charts – Utilizing visual scheduling tools effectively.

- Monitor & Optimize Performance – Regularly review KPIs and adjust workflows.

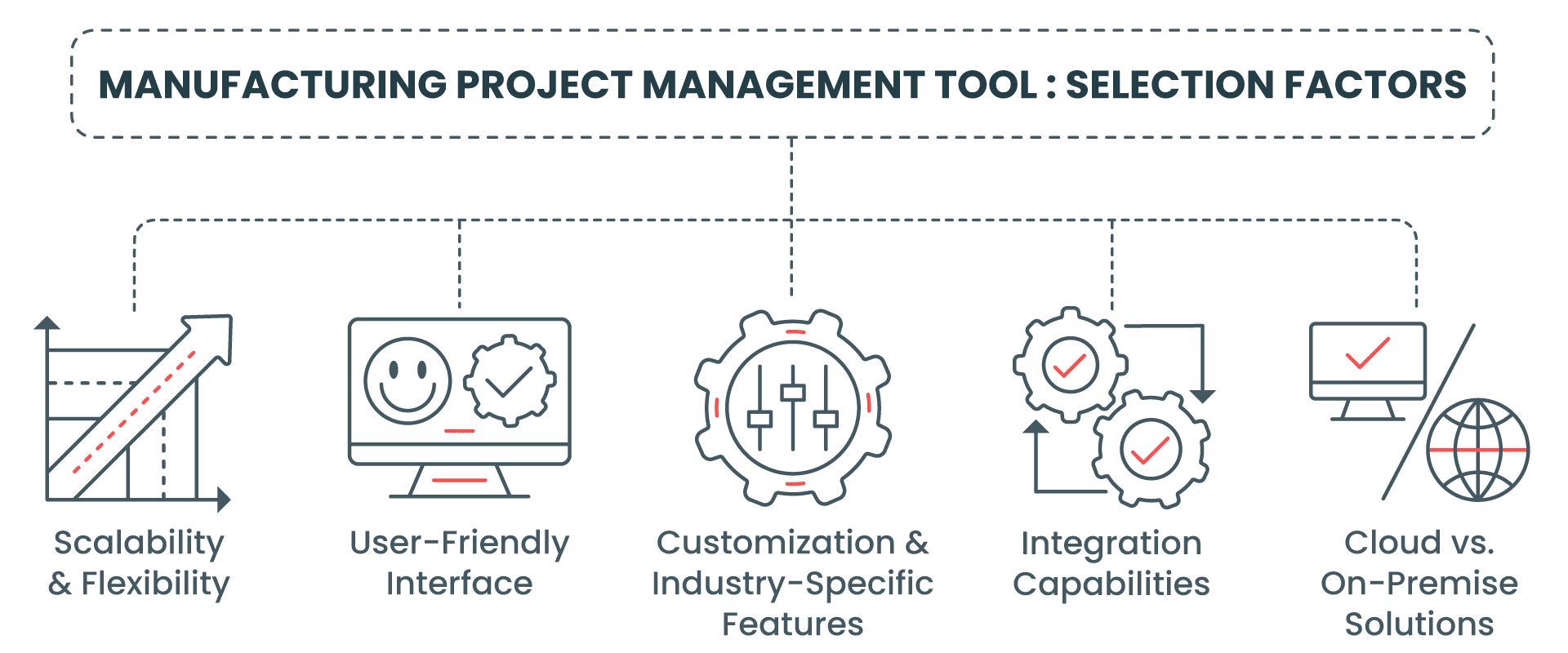

How to Choose the Right Software

Selecting the right manufacturing project management software requires careful evaluation of key factors to ensure it meets your company’s needs:

- Scalability & Flexibility – The software should support operations of any size, from small manufacturers to large-scale enterprises.

- User-Friendly Interface – A simple, intuitive design ensures adoption across technical and non-technical teams.

- Customization & Industry-Specific Features – Look for solutions tailored to manufacturing needs, such as production tracking and resource planning.

- Integration Capabilities – Ensure the software integrates with ERP, MES, and inventory management systems to maintain seamless data flow.

- Cloud vs. On-Premise Solutions – Weigh the benefits of cloud-based accessibility against the control and security of on-premise deployments.

Conclusion: What The Future Holds

Advanced project management software is revolutionizing manufacturing, integrating automation, AI, and real-time analytics to optimize processes. Investing in a robust solution ensures manufacturers remain competitive by enhancing efficiency, improving collaboration, and driving long-term success. As the industry evolves, manufacturers who adopt these tools will be best positioned for growth and operational excellence.

Task Management

Task Management

Customization

Customization